How Stolt Tankers conquered turbulent waters and found its way back to profitability.

Why and why now

Picture this: A huge tanker is charting its course, navigating through the vast oceans. The captain stands tall, giving orders to his crew, who respond promptly. But the sea is becoming more turbulent, and despite individual efforts to improve efficiency, the crew is struggling to truly turn the tide.

It is 2019, 60 years after Jacob Stolt-Nielsen created the first parcel tanker in the world. At the time, he did not know that the business he founded would go on to become the world’s largest chemical shipping company: Stolt Tankers. With a global operation and over 4.700 employees, both at sea and on shore.

But the past decades hadn’t been without their challenges. The biggest one – the company had not recouped its cost of capital over the previous 20 years. Lucas Vos (President of Stolt Tankers): “We were only achieving 5% returns on a yearly basis.

“You must understand: our business is tankers. Large vessels cross the oceans every day to transport liquid chemicals for our customers. These tankers require a lot of maintenance and need to be replaced after several years. That is why a 5% return is not enough for an asset-heavy company like ours to sustain its performance.”

The tricky part was that it didn’t feel like a burning platform. Instead, it was a slow roast. Stolt Tankers had simply been underperforming slightly for too long. So what changed? In 2017, the owner expressed the ambition to list his company on the stock exchange.

It was now or never: Stolt Tankers needed to turn the tides and find its way back to profitability. So the board made a brave decision and appointed a new President – Lucas Vos – to shake up the company, increase its sustained business performance, and prepare the company for an IPO.

Aye aye, captain

The main objectives to “turn the tide” were to (1) implement a World-Class Strategy and (2) transform the company while delivering day-to-day performance. Despite this clear vision, the transformation started as an uphill battle.

Traditionally, the ship (Stolt Tankers) had always been steered by its captain (the owner). Lucas: “Stolt Tankers was a hierarchical company, where decisions were made at the top. Also, it wasn’t treated as one company but rather as separate departments. The company had outgrown its structure, yet no alternative had been established. When the owner had an idea, people immediately started executing without asking themselves why we were doing it, or if there was a better way.”

“This kills your innovation culture,” Lucas says. “Ideas should come from all corners of the organisation. Especially if you want to digitise, introduce new ship designs and become a front runner in sustainability.” Besides bottom-up input, Stolt Tankers never had any outside-in steering either, nor managers coming from outside the industry. The company was somewhat stuck in its own routines and ways of working.

“Hierarchy kills your innovation culture. Ideas should come from all corners of the organisation. Especially if you want to digitise, introduce new ship designs and become a front runner in sustainability.”

Lucas Vos – CEO Stolt Tankers

At the same time, there was no clear business strategy or long-term vision of where the company was heading. “Each business unit created its own set of priorities, without considering the bigger picture,” says Bart Splinter (Business Support Manager at Stolt Tankers). “As you can imagine, the organisation was siloed as a result, which didn’t stimulate collaboration.”

The battery scan

While the context and history of Stolt Tankers demanded action, the big question was whether the organisation was ready for change. To determine this, LQ conducts what it calls a ‘battery scan’ at the start of any transformation program.

What does this mean? Many organisations lack the energy for change, on an emotional and/or rational level, which is needed to become successful. The Six Batteries of Change is the scientifically proven framework we’ve developed to measure the energy profile of an organisation and to guide it towards success.

By doing so, we can identify which interventions are needed to prepare the organisation for a successful transformation. In fact, 95% of change initiatives succeed when all the batteries are charged!

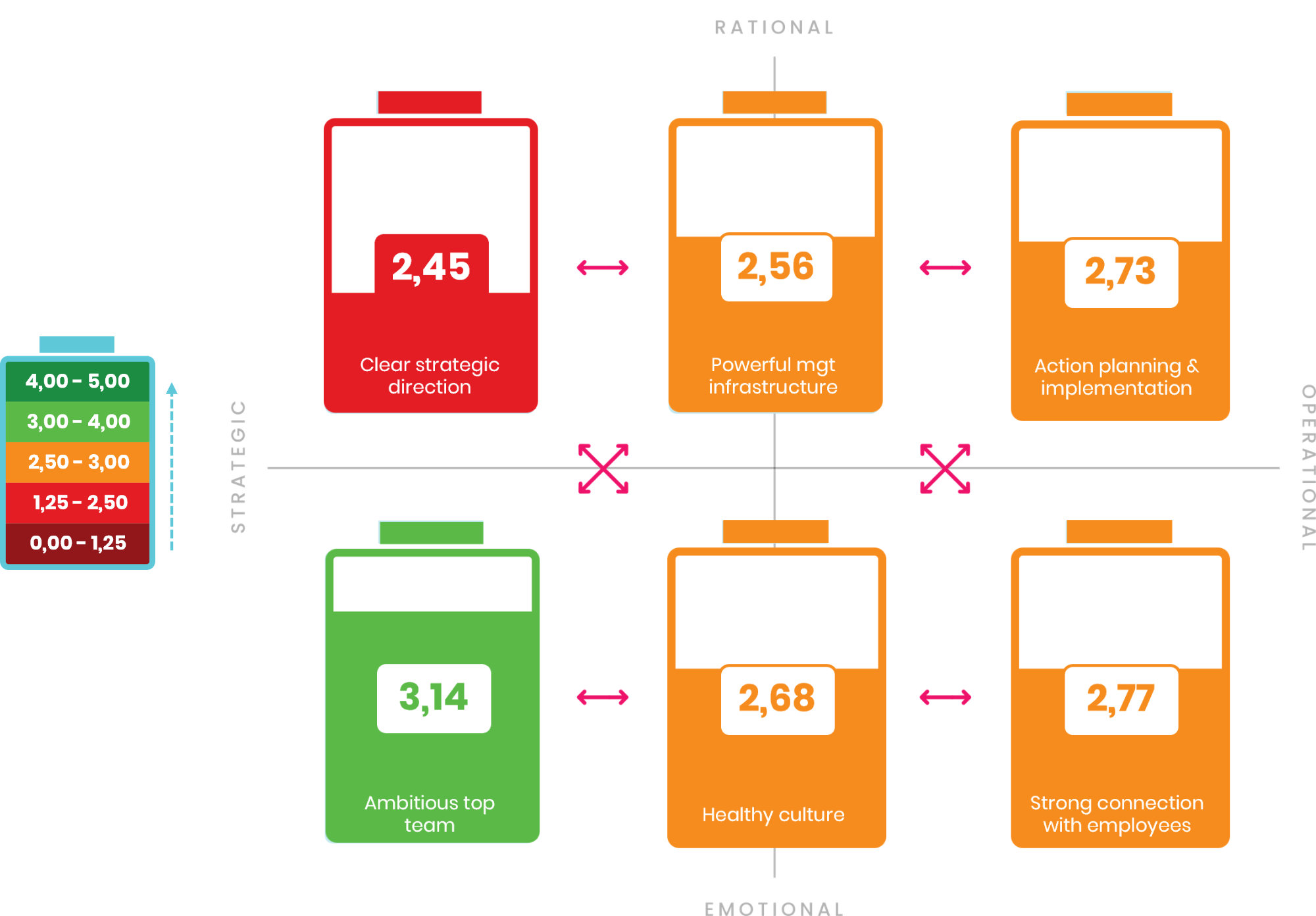

In the visual below, you can see the battery scores of Stolt Tankers as measured in 2019.

Note: Measurements were made after the appointment of Lucas Vos as CEO, which may already have impacted the Ambitious Top Team battery score.

As you can see, there was considerable work to be done, given the low to medium battery scores across the board. So what actions did Stolt Tankers take to improve in these areas and bring its transformation to fruition?

Learn more about the Six Batteries of ChangeMoments of truth

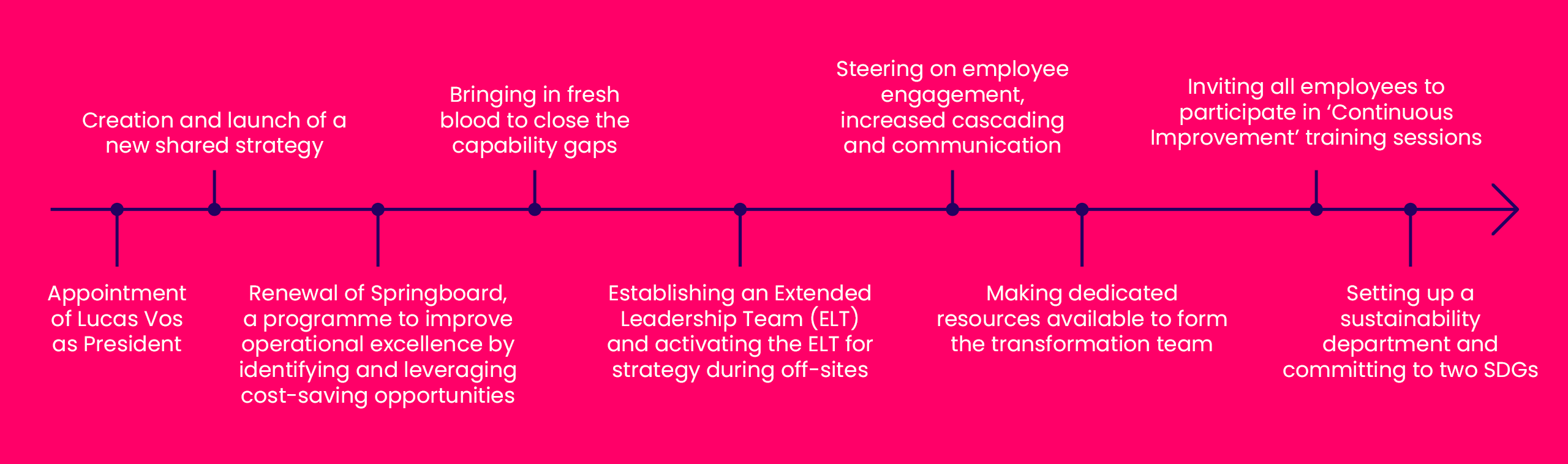

We asked the contributors to this story: Which events really moved the needle of this transformation? This is what they said.

- Appointment of Lucas Vos as President

- Creation and launch of a new shared strategy

- Renewal of Springboard, a programme to improve operational excellence by identifying and leveraging cost-saving opportunities

- Bringing in fresh blood to close the capability gaps

- Establishing an Extended Leadership Team (ELT) and activating the ELT for strategy during off-sites

- Steering on employee engagement, increased cascading and communication

- Making dedicated resources available to form the transformation team

- Inviting all employees to participate in ‘Continuous Improvement’ training sessions

- Setting up a sustainability department and committing to two SDGs

Keep reading to discover how each of these interventions made a difference.

Implementing the World-Class Strategy

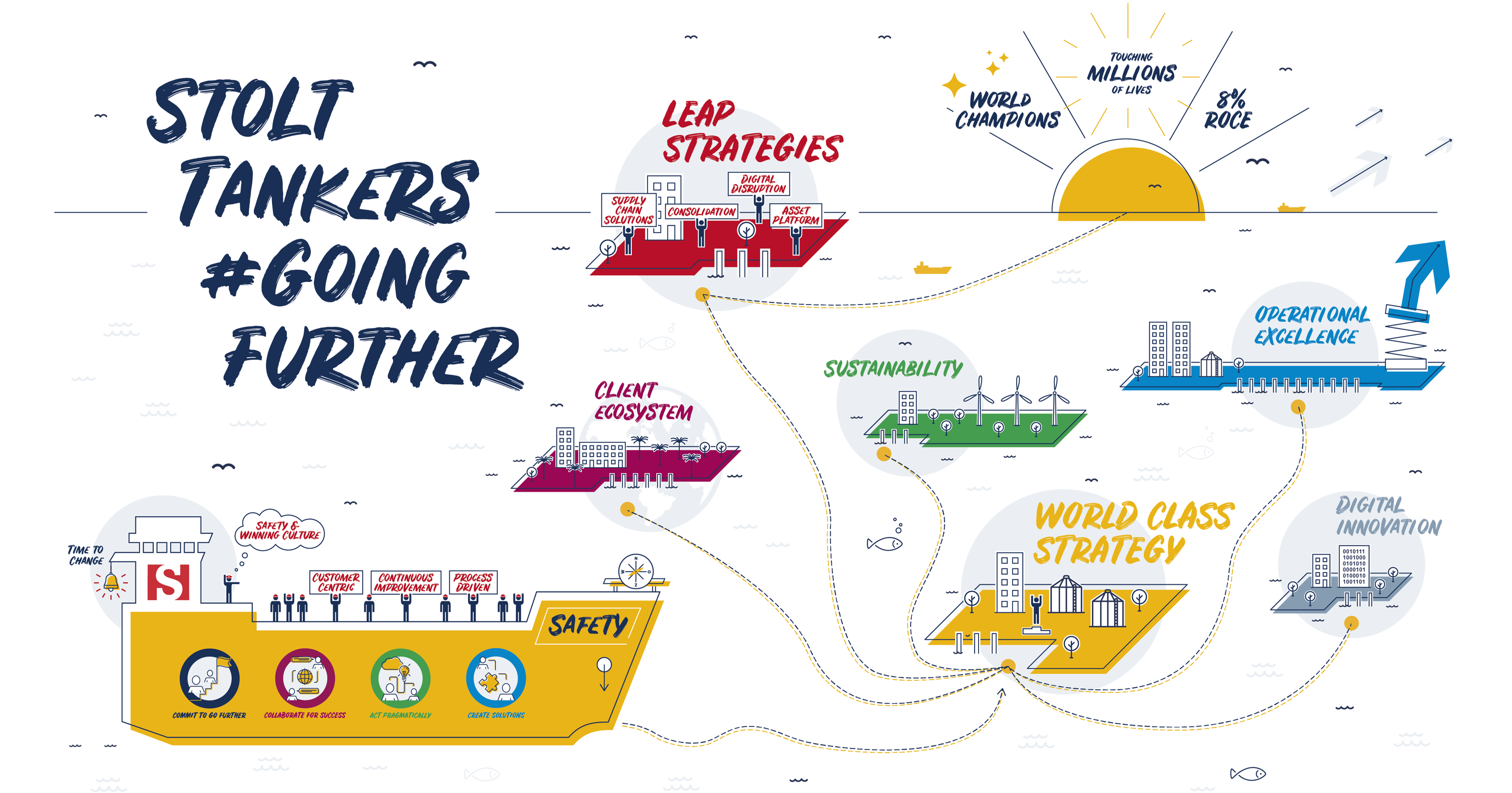

No ship sets sail without a compass and a destination. It was high time to create a clear strategic direction and launch the ‘World-Class Strategy’, which focused on three core elements:

- Improving operational excellence with Springboard

- Advancing our sustainability efforts

- Moving the needle in commercial excellence

Besides these immediate priorities, the company devised long-term ‘leaps’ to reinvent the business. These include adjusting its position in the supply chain, reconsidering the type of assets in which it invests and digitalising customer interactions.

Launching the strategy was the first big hurdle in this journey. Donald Bogden (Director Investment and Asset Management): “At the beginning, we needed to earn the trust of a shareholder. Their returns had been terrible for a decade.” As a result, it took time to get aligned on the strategy.

“For the first time, we had a proper business strategy in place, that we continued to talk about. I started every presentation with the picture of the four islands. And we made dedicated resources available to form a transformation team and execute the strategy.” These actions signalled that Stolt Tankers was dead-serious in its attempt to take charge of the situation. “People really liked that and I was surprised at how quickly they adopted the changes.”

“Typically, in shipping, there are good and bad seasons,” says Bart. “And during those rough years, there was a certain mentality in the organisation: let’s put our best foot forward every day and hope for the best. When Lucas came in, he had a clear strategy in mind and asked people to contribute to it. That was an eye-opener for the entire organisation.”

Also, it became easier for individuals to contribute. Harish Chand (Pool Manager at Stolt Tankers): “I’m in fleet development, and to execute, we always lacked buy-in from top management. With a business strategy in place, this became easier, because everybody was on board with the general direction. We needed to grow, which also meant making certain investments in our fleet.”

“With a business strategy in place, getting buy-in became easier, because everybody was on board with the general direction.”

Harish Chand – Pool Manager Stolt Tankers

But a strategy on paper is nothing more than that. To mobilise the workforce behind it, all the batteries needed to be charged.

Mobilising leadership

What was one of the energy drainers at the start of this transformation? There was a capability gap in the leadership team. As Lucas points out, “I had to do a lot of things myself. I started to see what was needed, but I had no way of executing it. That’s a problem.” So Lucas was determined to build an ambitious top team, which also meant letting certain people go and bringing in fresh blood.

Additionally, Lucas established an Extended Leadership Team (ELT) to shorten the distance between top and middle management. Geert Letens (Founding Partner – Director Research & Thought Leadership at LQ) explains: “Clear strategic direction had the lowest battery score, closely followed by a powerful management infrastructure and healthy culture. Sometimes, the head of an organisation (top management) is thinking straight, and the legs (the workforce) are powered up to run. But something is missing in the middle.” Setting up an ELT creates a bridge between the Ambitious Top Team and middle management.

What happened when the ELT was in place? “We organised a physical, three-day offsite, where all 30+ global leaders came together”, says Anne Kloosterboer (co-CEO Strategy, Clients and Partnerships at LQ). “This played a critical role in the business strategy cascade process, as well as in developing the ELT as a team. They came out of the event feeling a deep level of ownership for implementing the strategy.”

“Our team had just gone through a major transition,” says Emile Hoekstra (CFO Stolt Tankers) about the off-site. Open feedback was needed to build trust. “I remember we had to stand in a circle and one person stood in the middle to receive tips on what they needed to grow or prune. It was awkward, but very effective. It helped us get rid of our fear and engage in open dialogue.”

This has trickled down to the rest of the organisation. Donna Price (Global HR Business Partner Stolt Tankers): “We want people to speak up. And they do. Nowadays, we get more nitty-gritty and tough questions, because the leadership team feels more accessible.”

“We want people to speak up. And they do. Nowadays, we get more nitty-gritty and tough questions.”

Donna Price – Global HR Business Partner Stolt Tankers

Learning to speak the same language

It might sound as though everything before 2020 was bad, but that’s far from the truth. Jordi Bogaard (Technical Asset Manager at Stolt Tankers): “I was part of Springboard, a cross-functional team launched about a year before the transformation started. The objective? To identify and leverage cost-saving opportunities.

“By the time the strategy to return to profitability was created, we already knew what improvements we could make. We just didn’t know how to do it.” By which he means that there was no system in place (API), no dedicated resources, and culturally, many of his colleagues lacked the open mindset needed (HC) to contribute to the required changes (SC).

In order to charge the action planning and implementation battery, Springboard became a pilot for the Continuous Improvement (CI) programme. Lucas: “At the end of the day, it doesn’t really matter which method you’re using to streamline workflows. It’s all about embracing one methodology and learning to speak the same language.”

“It’s all about embracing one methodology and learning to speak the same language.”

Lucas Vos – CEO Stolt Tankers

The person appointed for this job was Sander van Geffen (Global Director Transformation at Stolt Tankers). “We installed a structure and provided basic CI tools to solve problems structurally and measure the outcome.” This resulted in a programme that made good progress. The Springboard team used a data-driven and systemic approach to identify and address major cost drivers (API), one by one (MI).

Moreover, it provided proof of concept. Suddenly, the whole organisation could see that Continuous Improvement worked. This brought the momentum needed to train the majority of employees in lean practices and foster a CI mindset. Lucas: “For me, this was the most important intervention in our transformation, as it gave every employee the tools to contribute to the strategy!”

Creating a lasting impact

One of the islands in the strategy revolves around ecological sustainability, which is a topic close to Lucas’ heart. “When I came in, I noticed that Stolt Tankers did not have a clear sustainability ambition or programme. Sustainability is a big reason why I am politically active. So I really pushed to get this on the agenda.”

A sustainability department was set up and the team identified two SDGs to focus on: climate and life below water. Maren Schroeder (Managing Director at Stolt Tankers): “Currently, we are building two separate strategies to make a lasting impact in these areas. There is still a lot of work to be done, and we’re actively trying to involve our customers in this journey.”

“Currently, we are building two separate strategies to make a lasting impact in the areas of climate and life below water.”

Maren Schroeder – Managing Director Stolt Tankers

But this is not the only area of interest to take the business forward. Bjarke Nissen (Managing Director at Stolt Tankers) is spearheading the customer-centricity program. “We need to strengthen the relationship with our key customers, in close collaboration with the digital team.” Another ongoing focus is standardisation of the fleet to improve utilisation and increase their ROCE – permanently.

The results

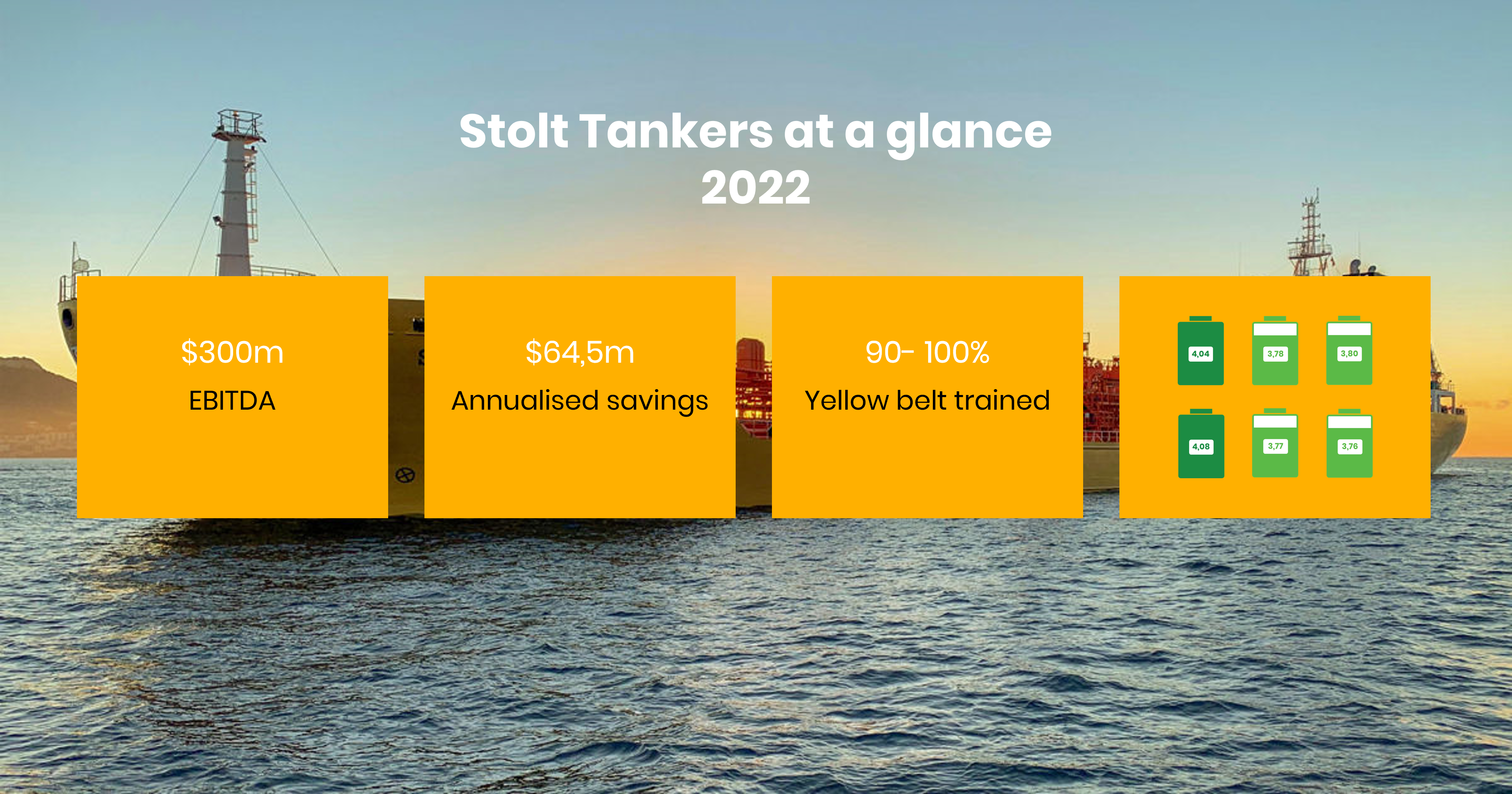

By implementing the World-Class Strategy, Stolt Tankers has become profitable again. In 2022, they outperformed their $300m EBITDA target by $50m, and 2023 is expected to bring a record-high EBITDA. In 2020-2022, Springboard has delivered $64,5m annualised savings in total (and an additional $14m prior to 2020).

But beyond financials, Stolt Tankers has managed to change its way of working. Sander: “You cannot express that in dollars. People experience better collaboration and more structured meetings, and they know how to implement improvements. 90-100% of them are yellow belt trained. But the biggest result for me: two to three years later, they are still putting their new skills into practice.”

In terms of healthy culture and powerful management infrastructure, there is more communication and better cascading. Donna: “Today, Stolt is a more inclusive organisation, where people can speak up and decisions are no longer being made in back rooms.”

So the results of the transformation are clearly visible in the hard (financial, operational) and soft (people, culture) performance metrics of Stolt Tankers. But equally important are the change capabilities they developed, which also became visible in the new battery scan in 2022.

Battery scores across the board have shown a significant improvement, indicating a strong top team (4.08), clear strategic direction (4.04), robust management infrastructure (3.78), healthy culture (3.77), effective action planning and implementation (3.80), and a strong connection with employees (3.76).

This is very encouraging, considering Stolt Tankers wants to have a lasting impact. Guided by a clear strategic direction and inspiring ambition that embraces the current challenges of the world, the company seems fully charged to face all potential transformation challenges that await it.

Full speed ahead Captain!

Epilogue

This transformation journey of Stolt Tankers can truly be seen as a best practice case study.

To begin with, it delivers on all the criteria for success. Transformations can only be considered successful if they drive the financial and operational performance of the overall organisation. This implies boosting the performance of all the batteries of change. In other words, successful transformations build the plane while they are flying it: they develop the change capabilities they need while delivering on business results, as well as articulating goals that aim to contribute to a better world.

As Stolt Tankers clearly illustrates, this is a journey of leadership that systematically has grown throughout the organisation. The passion and commitment of the CEO is key, but without the support of the whole leadership team, it would be no more than a cry in the dark. An ambitious top team is essential, but without the alignment and buy-in of the ELT, the ambition would remain an idle dream. And, ultimately, the ELT needs the inputs and support of key employees to turn the wheels that can change the ship’s course. Successful change is always about developing a critical mass of change ambassadors within the organisation.

As indicated by the initial battery results, Stolt Tankers’ journey needed to start with the batteries on the left-hand side: building a top team whose members grow towards each other through the creation of a clear strategic direction. Charging the middle batteries can be challenging, and this generally requires both a top-down and a bottom-up movement. The collaboration with Stolt Tankers’ ELT emphasises the importance of aligning key managers with the overall orientation of the organisation. The structure and guidance provided by the Springboard illustrates the value of the bottom-up motion. Eventually getting to tangible results involves equipping employees with a simple, shared methodology that they can use to continuously change and refine their own environment. This type of involvement ultimately leads to fully-charged batteries on the right-handed side: these are typically found in organisations driven by self-directing teams.

As Stolt Tankers develop their new change capabilities, the shift in the organisational culture is becoming visible as well. All of the key dimensions for a culture of change are being tackled. As the teams grow towards each other, both the hierarchical distance and the silo mentality are being reduced. Introducing new external members to the teams fills particular capability gaps while simultaneously introducing an outside-in perspective to replace the initial inside-out view. As the ambition grows, the performance orientation of Stolt has shifted as well. Financial results that assure the long-term health of the organisation have become central to decision making, but not at the expense of society. On the contrary, by developing sustainability goals, Stolt Tankers now provides a context for employees to connect their individual purpose with the long-term success of their organisation.

A remarkable example of how energising for success can bring people together for the betterment of all. My compliments to the LQ colleagues who guided this journey: well done, team!

LQ team

The

experts of

this story

Geert Letens

Founding partner - Director Research & Thought Leadership

Anne Kloosterboer

co-CEO | Strategy, Clients & Partnerships

Lianne Dingemanse

Business transformation manager